We are pleased to have invested in Opsydia, a University of Oxford spinout and specialist laser technology company which utilises decades of academic excellence and experience in adaptive optic beam shaping for writing features and functionalities in transparent materials.

We have invested in Opsydia, a leader in direct laser writing using adaptive optics. There are many applications for this technology, but the company’s principal focus will be on using its capabilities to write optical waveguides for optical interconnects in a manner that overcomes the limitations of current fabrication techniques.

This investment will allow the team to develop its technology to the point where it can fulfil sample requests from the major semiconductor manufacturers and to deliver at least one system to an end-user.

Background

Opsydia was spun-out in 2017, specialising in advanced laser technology for writing in transparent materials. The company’s initial focus has been the placement of unique identifiers within gemstones without affecting their quality – enabling identity, branding and traceability. Despite winning early orders, the company has had limited traction selling its systems to the gemstone industry. However, there are significant opportunities for its technology in the high growth photonics industry instead. Its existing systems will be re-engineered to enable them to produce optical waveguides for optical interconnects in a manner that overcomes the limitations of current fabrication techniques.

The Technology

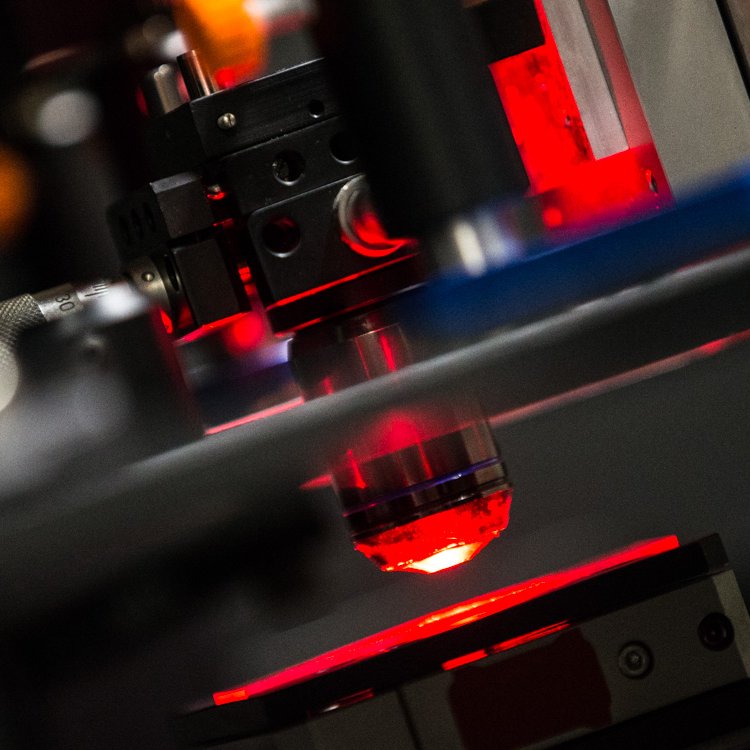

The technology is direct laser writing using adaptive optics developed at Oxford University.

An ultrafast laser beam is delivered to a work piece having first been adapted such that any optical aberrations encountered in the system are compensated. This allows for delivery of optimal laser beams to the target area, enabling more precise writing of features. By moving the laser beam through the glass, it is possible to write structures of interest, including optical waveguides, which can be used to move light from one place to another in an efficient manner.

Using highly sophisticated microscopy/machine vision, and high resolution motion control, it is possible to precisely locate the desired origin and termination points. This ensures that the written waveguide is in exactly the correct location. This point-to-point characteristic of the technique allows for low loss propagation of light, without the need for the time consuming active alignment step, which is currently an undesired necessity in the photonic packaging industry.

Other direct laser writing techniques cannot write to the edge of the glass connector block. The block must subsequently be polished to reveal the waveguide making for a more complex, costly process that is not clean-room compliant. This means that the active alignment problem is still present as the device can only be inserted after the waveguide is written and the block polished. Opsydia has overcome this limitation allowing users to directly write the waveguides in the correct position thereby remove unnecessary steps and increasing the amount of light transmitted

The adaptive optics approach is also required for writing waveguides at different depths in material. This is a critical goal for the industry as it seeks to move from 1 dimension connector arrays to 2 dimensional arrays and more complex device architectures.

To find out more about Opsydia, visit their website or our portfolio page here.