Parkwalk portfolio company Opsydia has secured the first order for its Opsydia D5000 Diamond Marking System. The sale, to industry giant De Beers for their Lightbox Jewelry business, follows over a year of development work and is a major step forward for Opsydia’s ground-breaking technology that helps address tampering and counterfeiting in diamonds.

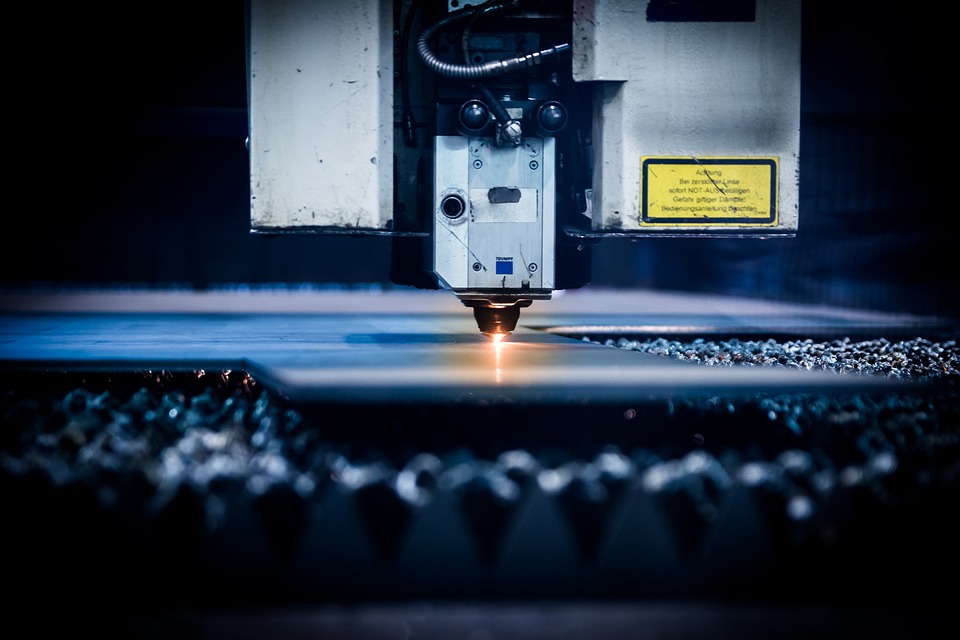

Using a high precision laser, the Opsydia D5000 can make marks less than 1/50th of the size of a human hair. Unlike current surface marking techniques, these tiny marks are secured below the surface of gemstones so that they cannot be polished off economically. The sub-surface marks can be so small that they have no effect on the grading or quality of the gems.

After proving the concept within the laboratory of the University of Oxford’s Department of Engineering Science, Opsydia began work to scale the laser process for use in diamond processing facilities at high volumes. The result is the Opsydia D5000, which allows customers to apply Opsydia’s secure marking technology on an industrial scale. Early adopters of the technology were De Beers Group’s new lab-grown diamond initiative, Lightbox Jewelry, which is using the sub-surface laser marks to distinguish lab-grown diamonds from natural and serve as a guarantee of quality.

“Opsydia’s technology has already proven itself to be a highly effective method of including a quality mark and tamperproof tag into our laboratory grown diamonds. We are excited to now be purchasing our first D5000 marking systems from Opsydia, which will support the significant expansion of our production in 2020 as our new manufacturing facility near Portland, Oregon in the US comes on line” said Steve Coe of Lightbox.

The technology can also be used more widely in the jewellery industry to increase security and confidence in the quality and provenance of stones. Opsydia will be demonstrating how this can work to at the jewellery industry’s leading trade show, JCK in Las Vegas, starting on 31 May.

“Having been adopted by one of the iconic names in the diamond industry, we aim to show the wider diamond, gemstone and jewellery community how our laser technology can transform security and support initiatives to prevent counterfeiting and tampering,” said Andrew Rimmer, CEO of Opsydia.

Opsydia’s technology uses laser pulses shorter than one trillionth of a second in length to create tiny lines which can be written as numbers or logos within the diamond. The marks are invisible to the human eye and the smallest ones are not detectable with a jeweller’s loupe, but can be viewed using a microscope. Marking in any facet of the stone means security can be maintained even when gems are mounted in jewellery.

Opsydia’s technology can also be used to securely mark any translucent material, such as plastics and polymers, and the company also envisages future applications writing electrical circuits within industrial diamond to create advanced sensors.